How Sintered Gerotors Improve Engine Efficiency and Oil Flow Stability

In modern vehicles and machinery, achieving high engine efficiency and stable oil flow is crucial for optimal performance and longevity. A key technology contributing to this is the sintered gerotor, a component used in many engines and pumps to ensure smooth and reliable oil circulation. By understanding how sintered gerotors work, we can appreciate their significant impact on engine efficiency and the stability of oil flow.

Understanding Sintered Gerotors

A sintered gerotor is a type of gear mechanism commonly used in engine oil pumps and hydraulic systems. Unlike traditional gears, sintered gerotors are made through a sintering process, which involves compressing metal powder into a solid form and then heating it to bond the particles together. This creates a more durable, lightweight, and cost-effective part compared to traditional materials.

- Traditional Gerotors: These are typically made from solid metal and rely on precision machining to form the gears. While effective, they tend to be heavier and more expensive to produce.

- Sintered Gerotors: The sintering process allows for more complex shapes to be formed, often resulting in lighter parts with a lower cost of production. Additionally, the porosity of sintered parts can help with lubrication, reducing friction and wear.

The Sintering Process: Benefits for Gerotor Design

The sintering process involves compacting metal powder into a mold and then heating it in a furnace. During this process, the powder particles fuse together, forming a solid, strong material. The benefits of using sintered materials for gerotors include:

- Cost-effectiveness: Sintered gerotors are cheaper to manufacture compared to traditionally machined ones.

- Strength and Durability: The sintering process creates a material that is highly durable, reducing wear and tear during operation.

- Improved Oil Flow: The porosity in sintered gerotors can help retain a small amount of oil within the material, further reducing friction and improving the stability of oil flow through the system.

Role of Gerotors in Engine Systems

Gerotors are critical components in many engine systems, particularly in oil pumps and hydraulic systems. They help maintain a consistent flow of oil, ensuring that engine parts are properly lubricated, which is essential for preventing friction and wear.

- How Gerotors Function: Gerotors work by using a set of interlocking gears that create chambers for oil to move through. As the gerotor rotates, the size of these chambers changes, causing the oil to flow smoothly through the system. This helps maintain a consistent pressure in the engine’s oil system.

- Applications: Gerotors are widely used in automotive engines, industrial pumps, and hydraulic machinery, where reliable oil circulation is necessary. In vehicles, they ensure that the engine components are lubricated under a wide range of conditions, from start-up to high-speed operation.

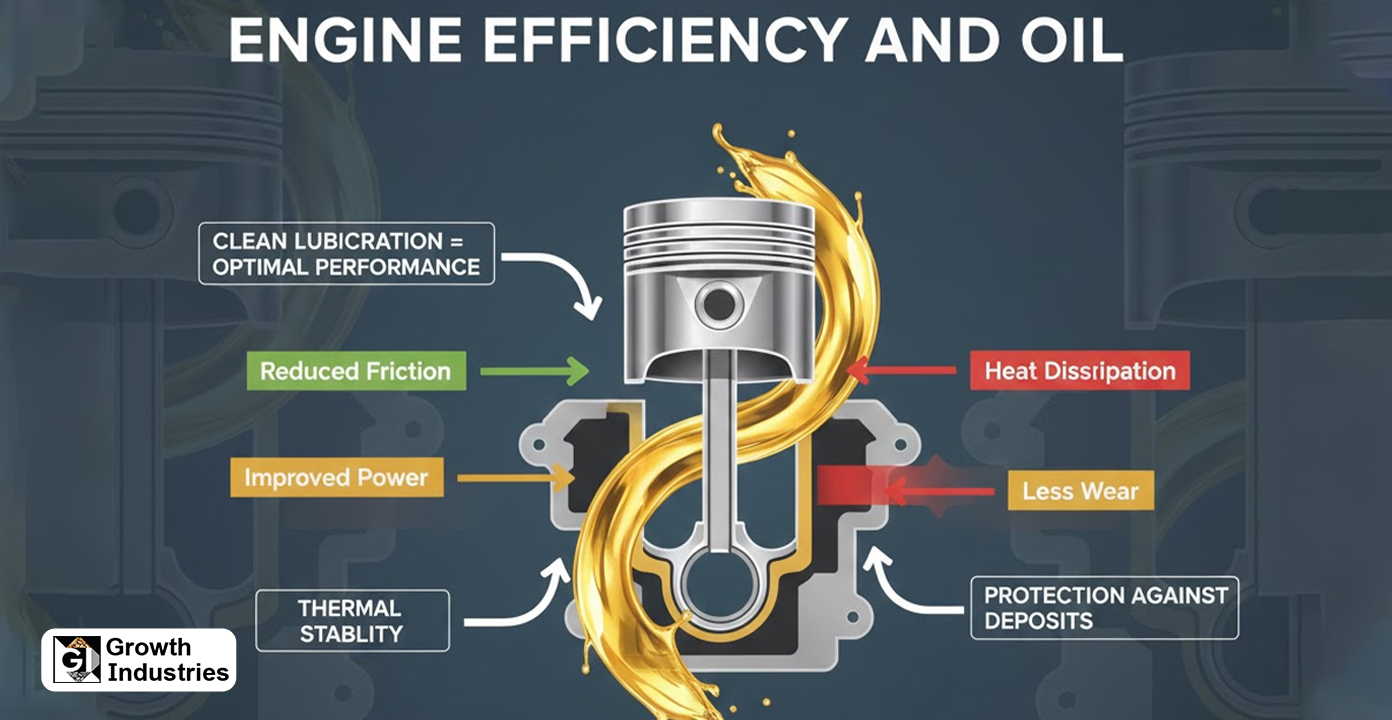

- Oil Flow Importance: In any engine, proper oil flow is critical for maintaining engine health. Oil acts as a lubricant, reducing friction between moving parts. It also helps to carry heat away from engine components, preventing overheating. A stable oil flow, facilitated by gerotors, ensures that the engine operates efficiently and that all components remain well-lubricated under all conditions.

By using sintered gerotors, manufacturers can enhance engine efficiency and oil flow stability, leading to better performance and longer-lasting machinery.

Sintering: A Game Changer for Gerotor Performance

The sintering process is a critical advancement in gerotor manufacturing, significantly improving material properties and performance.

- Enhanced Material Properties: Sintering improves key material characteristics like hardness and porosity. Sintered gerotors are typically more durable than traditionally machined ones, thanks to a stronger bond between particles. The slight porosity in the sintered material can help retain lubricants, reducing friction and wear. This ensures smooth operation over extended periods, even under harsh conditions.

- Advantages Over Cast and Machined Gerotors: Sintered gerotors are more lightweight compared to cast or machined options. The sintering process allows for more intricate designs, reducing material wastage. The process also eliminates the need for extensive post-machining, making sintered parts cheaper and faster to produce. Additionally, sintered gerotors often exhibit better resistance to wear due to their uniform material properties.

- Cost-effectiveness and Manufacturing Benefits: One of the biggest advantages of sintering is its cost-effectiveness. Sintered parts are produced with less waste and reduced energy consumption compared to traditional casting or machining methods. The ability to produce complex geometries with minimal material allows manufacturers to reduce costs while maintaining performance and durability.

Applications of Sintered Gerotors in Different Industries

Sintered oil gerotors find wide use across various industries due to their durability, reliability, and performance. Some of the primary applications include:

- Automotive: In vehicles, sintered gerotors are primarily used in engine oil pumps and fuel pumps. They ensure the efficient circulation of oil and fuel, crucial for smooth engine operation. The precision of the sintered gerotor helps maintain stable oil flow, preventing engine wear and improving fuel efficiency.

- Industrial Machinery: Sintered gerotors are used in hydraulic systems and industrial pumps. They ensure consistent fluid transfer, crucial in machinery that requires reliable performance under high-pressure conditions. In construction equipment, manufacturing machines, and other heavy-duty machinery, sintered gerotors help reduce downtime and improve system efficiency.

- Aerospace and High-Performance Applications: In the aerospace industry, where reliability is paramount, sintered gerotors are used in fuel systems and hydraulic pumps. They help maintain precise oil and fluid flow in high-pressure environments, ensuring the smooth operation of critical components. Their lightweight and durable nature make them ideal for reducing weight while maintaining strength.

Case Studies: Real-World Impact of Sintered Gerotors

Several industries have seen remarkable improvements by incorporating sintered gerotors into their systems. Here are some examples:

- Automotive Industry: A leading car manufacturer integrated sintered gerotors into their engine oil pumps. The result was a 10% improvement in fuel efficiency due to the enhanced oil flow, which reduced engine friction. Additionally, the durability of the sintered gerotors reduced the frequency of maintenance by 15%, cutting overall repair costs.

- Industrial Machinery: A construction equipment manufacturer implemented sintered gerotors in their hydraulic systems. The use of sintered components led to a 20% reduction in system failures due to better fluid flow and reduced wear, saving the company significant downtime and maintenance expenses.

- Aerospace: In a high-performance jet engine, sintered gerotors were used in the fuel system. These parts improved fuel delivery efficiency and reduced the weight of the fuel system by 8%. The result was enhanced overall performance and lower fuel consumption during flight.

These case studies highlight how sintered gerotors can significantly improve performance metrics such as fuel efficiency, maintenance costs, and system reliability.

Challenges and Considerations

Despite their numerous advantages, the use of sintered gerotors does present some challenges and considerations:

- Potential Limitations: Sintered parts may not be suitable for all applications. While they offer excellent durability and wear resistance, they may not perform as well in extremely high-temperature environments where the material might degrade or lose its strength. In these cases, other materials or manufacturing methods might be necessary.

- Factors to Consider When Choosing Sintered vs. Traditional Gerotors: When selecting between sintered and traditional gerotors, manufacturers should consider factors like application requirements, environmental conditions, and cost constraints. Sintered gerotors offer significant advantages in cost and material efficiency but may not always be the best choice for every application. For example, if extreme precision or the ability to withstand extremely high pressures is needed, a traditional machined gerotor might be more appropriate.

The Future of Sintered Gerotors in Engine Technology

As technology advances, so too does the potential for sintered gerotors to play an even more significant role in enhancing engine performance and oil flow stability. Here are some emerging trends and innovations shaping the future of sintered gerotors:

- Emerging Trends in Gerotor Design: The focus is shifting towards creating lighter, stronger, and more efficient gerotors. With advancements in 3D printing and additive manufacturing, it’s now possible to design more complex shapes and structures that were previously impossible or too expensive to create using traditional methods. This can further reduce weight while enhancing the strength and functionality of gerotors.

- Advanced Materials: Innovations in materials science are pushing the boundaries of what’s possible with sintered gerotors. Future gerotors may incorporate advanced composite materials or nano-coatings that improve wear resistance, reduce friction, and increase the lifespan of engine components. For example, using graphene-infused or ceramic-based sintered materials could enhance the durability of gerotors in high-temperature environments, such as in racing or aerospace applications.

- Smart Gerotors: The future of gerotor technology might also involve the integration of smart sensors and IoT capabilities. These sensors could monitor the performance of the gerotor in real time, providing feedback on factors like oil flow, temperature, and pressure. This data could then be used to optimize engine performance, allowing for adaptive systems that automatically adjust to varying operating conditions.

- Improved Engine Performance: With the advent of new materials and designs, the next generation of sintered gerotors could significantly enhance oil flow stability in engines. By improving the consistency of oil circulation, engines could operate more efficiently, reduce wear, and ultimately result in lower emissions and better fuel economy.

As these innovations unfold, we can expect sintered gerotors to become even more integral to next-generation engine systems, supporting advancements in energy efficiency, performance, and longevity.

In summary, sintered gerotors represent a critical advancement in engine technology, offering significant improvements in oil flow stability and engine efficiency. The benefits of sintered gerotors are clear:

- Cost-effectiveness: The sintering process allows for more affordable production, without sacrificing quality.

- Enhanced Durability: Sintered gerotors are stronger, lighter, and more wear-resistant than traditional machined or cast gerotors.

- Improved Engine Performance: With their ability to maintain stable oil flow and reduce friction, sintered gerotors contribute to smoother, more efficient engine operation.

Looking to the future, the role of sintered gerotors in engine technology is poised to grow as new materials and design innovations unlock even more possibilities for improving performance, reducing costs, and enhancing durability. Whether in automotive, industrial, or aerospace applications, sintered gerotors will continue to be a key player in achieving more reliable, high-performing engines. Their contribution to oil flow stability and engine efficiency will be central to the development of future vehicle and machinery technologies.