Sintered Oil Pump Gerotors: Design, Function, and Applications

Oil pumps are critical components in automotive engines and industrial hydraulic systems, ensuring consistent lubrication and smooth operation of moving parts. Among the different types of oil pumps, gerotor pumps stand out for their compact design, efficiency, and ability to handle varying viscosities of lubricants. With the advent of sintered metal technology, gerotors have become even more durable, precise, and cost-effective, making them a preferred choice in modern machinery.

Gerotors, short for “generated rotors,” are specialized internal gear pumps comprising an inner rotor and an outer rotor. The inner rotor has one tooth less than the outer rotor, creating expanding and contracting chambers as it rotates. This motion draws fluid in, traps it, and then discharges it efficiently. Gerotors are commonly used in engines, hydraulic systems, and other industrial machinery where precise fluid delivery is essential.

Key advantages of gerotors:

- Smooth, continuous flow of oil.

- Compact and lightweight design.

- Lower noise compared to conventional gear pumps.

Understanding Sintered Metal Technology

Sintering is a process where powdered metals are heated below their melting point to bond particles together, forming a solid, dense material. This technique is widely used in manufacturing gerotors because it allows for precise shapes, uniform density, and excellent wear resistance.

Benefits of sintered components:

- High strength and durability.

- Ability to produce complex geometries without machining.

- Reduced production costs and waste.

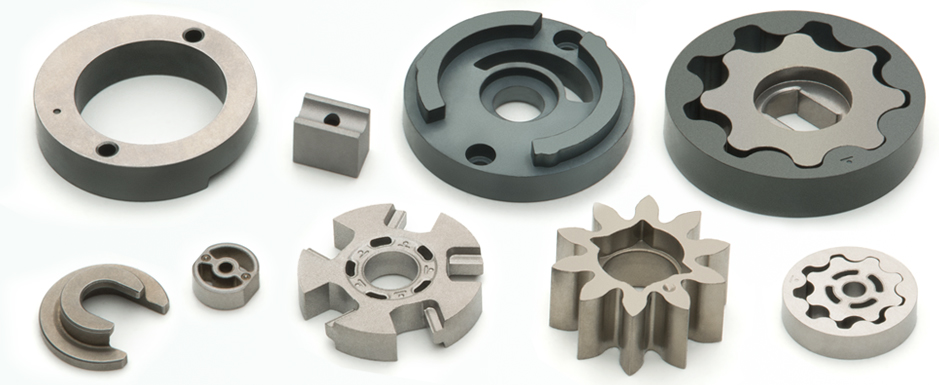

Design and Construction of Sintered Oil Pump Gerotors

Sintered gerotors typically consist of:

- Inner rotor: Usually a star-shaped rotor with fewer teeth than the outer rotor.

- Outer rotor: Ring-shaped with internal teeth to mesh with the inner rotor.

- Housing: Encases the rotors, ensuring fluid containment.

Material selection is critical; sintered steel or iron alloys are preferred for their strength, hardness, and corrosion resistance. High precision in tolerances ensures smooth operation, while surface finishing reduces friction and wear.

The working process involves:

- Intake: Oil enters the expanding chamber between inner and outer rotors.

- Trapping: The oil is trapped as the chamber rotates, maintaining a sealed environment.

- Discharge: As the chamber contracts, oil is pushed out under pressure.

This mechanism provides a continuous, steady flow of oil, ensuring lubrication consistency. Compared to other pumps like gear or vane pumps, gerotors operate more quietly and efficiently under varying load conditions.

Advantages of Sintered Oil Pump Gerotors

- Durability: Sintered metals resist wear, abrasion, and high-temperature conditions.

- Efficiency: Precise geometry reduces leakage and maximizes volumetric efficiency.

- Cost-effectiveness: Sintering allows mass production at lower costs.

- Smooth operation: Reduced noise and vibration improve overall system performance.

- Lightweight design: Helps in automotive applications where weight reduction is crucial.

Common Applications

Sintered gerotor pumps are versatile and used in:

- Automotive engines: Lubricating passenger cars, trucks, and motorcycles.

- Industrial hydraulics: Operating machinery in factories and construction equipment.

- Marine and aerospace: Ensuring reliable lubrication in engines and hydraulic systems under extreme conditions.

Performance Optimization Tips

To maximize the performance of sintered gerotors:

- Use high-quality lubricants suitable for the operating temperature.

- Ensure tight manufacturing tolerances to prevent leakage.

- Apply surface coatings or treatments to reduce wear and extend lifespan.

- Regularly monitor oil quality and filter debris to prevent pump damage.

Troubleshooting and Maintenance

Common issues with gerotors include:

- Wear or scoring: Caused by contaminated oil or insufficient lubrication.

- Cavitation: Due to improper oil flow or low suction pressure.

- Leakage: From worn rotor tips or housing clearance.

Maintenance tips:

- Inspect rotors and housing periodically for wear.

- Replace damaged or worn gerotors promptly.

- Maintain proper oil viscosity and cleanliness.

Future Trends

The field of sintered gerotor technology is evolving:

- Advanced materials: Development of lightweight, high-strength alloys for longer life.

- EV and hybrid applications: Efficient lubrication systems for electric and hybrid drivetrains.

- Smart sensors: Integration of monitoring systems to predict maintenance needs and improve efficiency.

Sintered oil pump gerotors combine precision engineering with durable materials, offering efficient, reliable, and cost-effective solutions for lubrication in engines and industrial machinery. Their compact design, smooth operation, and ability to withstand harsh conditions make them a key component in modern mechanical systems. Adopting sintered gerotors not only enhances performance but also extends the life of engines and hydraulic systems.