An oil pump rotor is a rotating component inside an oil pump that pushes engine oil through the lubrication system. It ensures that every moving part of an engine or machine receives the correct amount of oil for smooth and safe operation.

With the rise of sintered technology, these rotors have become stronger, more precise, and more reliable. Sintering uses metal powders and molds to create components with excellent strength, durability, and low friction. For oil pumps used in automobiles, tractors, industrial machines, and hydraulic systems, sintered rotors offer better performance at a lower cost.

This tiny component plays a big role—it keeps oil flowing, reduces wear, and protects the engine from overheating or failure.

A sintered oil pump rotor is a special type of rotor made using powder metallurgy (PM). Instead of cutting a rotor from a solid metal block, extremely fine metal powders are compacted in a die and then heated at high temperatures until the particles fuse. This forms a dense, durable, and accurate rotor shape.

Key points:

Sintered Rotors vs. Machined Rotors

| Feature | Sintered Rotor | Machined Rotor |

|---|---|---|

| Manufacturing | Powder metallurgy | Cut from solid metal |

| Cost | Lower | Higher |

| Lubrication | Self-lubricating porous structure | No natural lubrication |

| Accuracy | Excellent dimensional control | Depends on machining quality |

| Wear resistance | High | Moderate |

Sintered rotors have become the preferred choice in modern automotive and industrial pumps due to their consistency and long service life.

A sintered oil pump rotor is made from carefully selected metal powders pressed into a precise shape. The porous structure and composition give it its superior performance.

Common Materials Used:

Porous Structure & Self-Lubrication

During sintering, the metal particles bond together but also leave tiny air-filled pores. These micro-pores offer multiple advantages:

This unique structure is the reason sintered rotors perform better in high-speed and high-temperature environments.

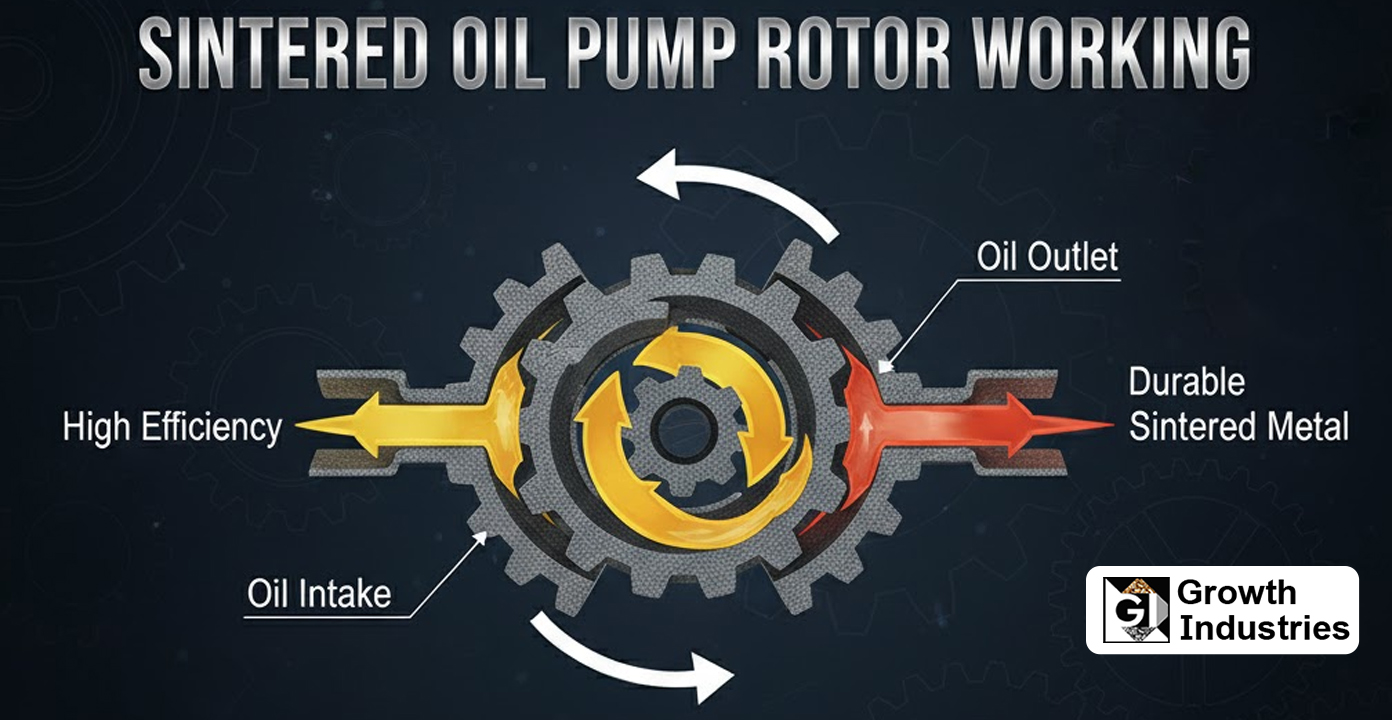

A sintered oil pump rotor generally works in a gerotor mechanism, which consists of two main parts:

The inner rotor is connected to the engine crankshaft. When the crankshaft rotates, the inner rotor rotates with it. The outer rotor has one additional tooth compared to the inner rotor and rotates inside the pump housing.

Because the inner rotor is placed off-center (eccentric position) inside the outer rotor, the space between their teeth continuously expands and contracts as they rotate. This expanding and contracting space creates a pumping action that:

This simple but highly efficient mechanism is why gerotor pumps are widely used in modern engines.

The working can be understood in three clear steps:

As the inner and outer rotors begin to rotate, the gap between some tooth chambers increases.

This creates a low-pressure area, and engine oil from the sump is drawn into the pump inlet.

As rotation continues, the previously expanded chambers start to close.

The trapped oil gets squeezed, and its pressure rises.

Finally, as the chambers fully contract, the high-pressure oil is forced out through the pump outlet and sent to:

The performance of the pump largely depends on:

Tight tolerances ensure:

Sintered rotors naturally offer these precise tolerances due to the powder metallurgy process.

A sintered rotor is an integral part of the gerotor-type oil pump assembly. It fits inside the pump housing and is driven either directly by the crankshaft or through a chain/gear drive.

It is compatible with:

Because of its dimensional accuracy and durability, sintered rotors are now standard in most modern oil pump designs.

The production involves several precise steps that deliver high strength, accuracy, and consistent performance.

Metal powders such as iron, alloy steel, or bronze are mixed with lubricants and binders.

This ensures uniform chemical composition and better flow during compaction.

The blended powder is filled into a die cavity and compacted under high pressure (up to several tons).

This forms the “green compact,” which already resembles the final shape of the rotor.

The compacted part is heated in a sintering furnace at temperatures close to the melting point.

During sintering:

A controlled atmosphere prevents oxidation and ensures high-quality bonding.

Some parts may need minor machining to achieve extremely tight tolerances.

CNC machines are used for:

Before dispatch, several tests are performed:

These checks ensure high reliability in demanding engine environments.

Powder metallurgy allows the creation of complex shapes with extremely tight tolerances, ensuring smooth pump operation.

The controlled material composition and surface finish make the rotor highly resistant to wear, even under continuous load.

Sintering requires less machining and less raw material, making it ideal for high-volume production at a low cost.

The porous structure traps lubricating oil inside the rotor. This reduces friction, heat, and wear.

Despite being lightweight, sintered rotors offer excellent mechanical strength and withstand high pressures easily.

Smooth tooth engagement and consistent clearances minimize vibration and noise inside the pump.

Used in:

They provide stable oil pressure for both high-speed and high-load driving.

Small engines benefit greatly from the precision and cost-effectiveness of sintered rotors.

Used in factories, CNC machines, hydraulic systems, and gearboxes where continuous lubrication is required.

Ensures steady lubrication for long hours of non-stop running.

Ships, loaders, excavators, and cranes rely on durable rotors for stable oil pressure.

| Parameter | Sintered Rotor | Machined Rotor |

|---|---|---|

| Efficiency | High due to tight tolerances | Moderate |

| Durability | Excellent wear resistance | Lower compared to sintered |

| Cost | Low for bulk production | Higher due to machining |

| Manufacturing Speed | Very fast (mass production) | Slow, multiple machining steps |

| High-Temperature Performance | Very stable due to material structure | Can deform or wear faster |

Sintered rotors clearly outperform traditional machined rotors in most categories.

Look for signs such as:

These indicate the rotor may be worn.

Using the correct oil grade improves lubrication and prevents premature wear.

Synthetic or semi-synthetic oils are preferred for modern engines using sintered rotors.